Being green products, Concrete Brick & Block and Fly Ash Brick making is a profitable business these days. Now you are asking if it is profitable? The answer is yes.

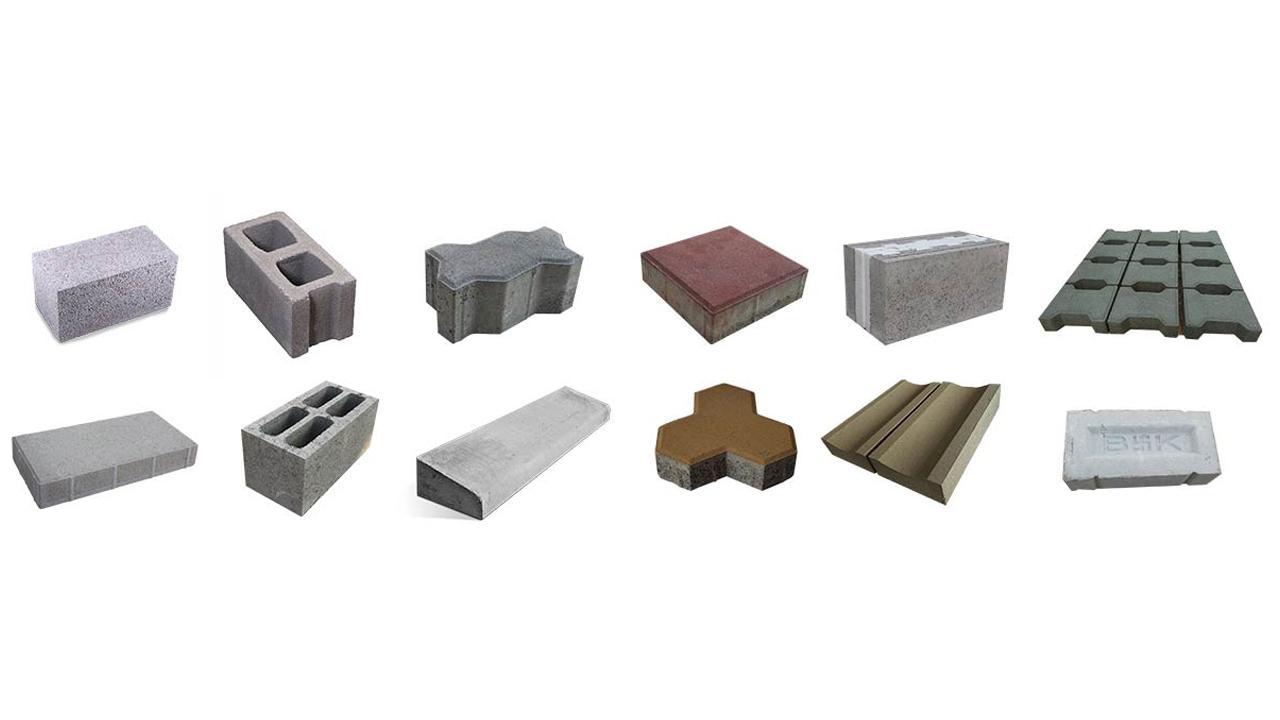

Concrete Block

In the initial stage, the business starts with a smaller machine with less automation and less production capacity. After the business grows, you can move to a bigger space with a bigger capacity of concrete block making machine or fly ash bricks machine.

ADVERTISEMENT

Cement Brick Manufacturing Business

The cement brick making business has visuals a high profit in recent years. There is confusion for many individuals if the cement brick making business will be successful or not. Let’s find out more details about it.

Nowadays, cement bricks are more popular than ever before. It is due to the increasing demand for construction activity in the country. These days the conventional red bricks are replaced by cement bricks due to the various advantages offered by it. These cement bricks have multiple advantages include faster construction speed, durability, less labor, and uniform quality. Today these cement bricks are used for a wide range of construction applications such as industrial buildings, residential buildings, and commercial buildings. Due to this, cement bricks are always in demand in both rural and urban areas. These cement bricks are lightweight compared to conventional bricks and easily placed.

Raw Materials

The size of the concrete cement bricks is larger compared to conventional clay bricks.

Cement

Stone Chips

Sand

Stone Dust

How to Choose the Best Concrete Brick Making Machine?

The selection of concrete brick making machine is depended on which type and how many quantities are required. Today there are numerous concrete block making machine manufacturers. And the quality of the block or brick is depending on the machine and it is varied from machine to machine.

There are different types of machines are available for making different types of blocks. Though there are also machines that can make multiple products from a single machine by simply changing the mold. So, it is depending on you which type of block you want to make.

There are various factors, that will help to choose the right machine.

Automation

There are mainly two types of automation available for concrete block making machine are fully automatic concrete block making machine and semi automatic concrete block making machine. The fully automatic machines are controlled by PLC and are easy to operate. While semi automatic machine has a human intervention. It has also a low production capacity compared to fully automatic. It is due to latest technology and features. These fully automatic machines are more expensive than semi-automatic ones.

Production Capacity

There are various models available of concrete block & brick making machine. Also, you do not have to buy fly ash brick making machine separately. As concrete block & brick making machine can manufacture fly ash brick. These machines come in capacity from 1000 to 10000 bricks or blocks per hour. You can select the right machine as per your need.

Mobility

There are two types of concrete block making machine based on movability, stationary type, and mobile. The mobile type block making machine is easy to move compared to the stationary type. If it is required to move block making machine frequently, the mobile type is suitable.

In the conclusion, in the brick making field, it is advisable to start a concrete block & brick making business on a small scale. The concrete block making business can be started at 300 square meter area and you can set up this plant in outskirts of the city which minimize the investment.

Subscribe today by clicking the link and stay updated with the latest news!" Click here!

Subscribe today by clicking the link and stay updated with the latest news!" Click here!