Home / Sunday-mid-day / / Article /

A sari story: Excerpts from The S Kumars Story by Sathya Saran

Updated On: 30 June, 2024 07:20 AM IST | Mumbai | Team SMD

Vibrant, synthetic sarees were once upon a time a groundbreaking innovation, and crushingly sophisticated. Our chosen excerpt from the newly released book Thread by Thread, The S Kumars Story by Sathya Saran, captures this sartorial revolution and how it spread

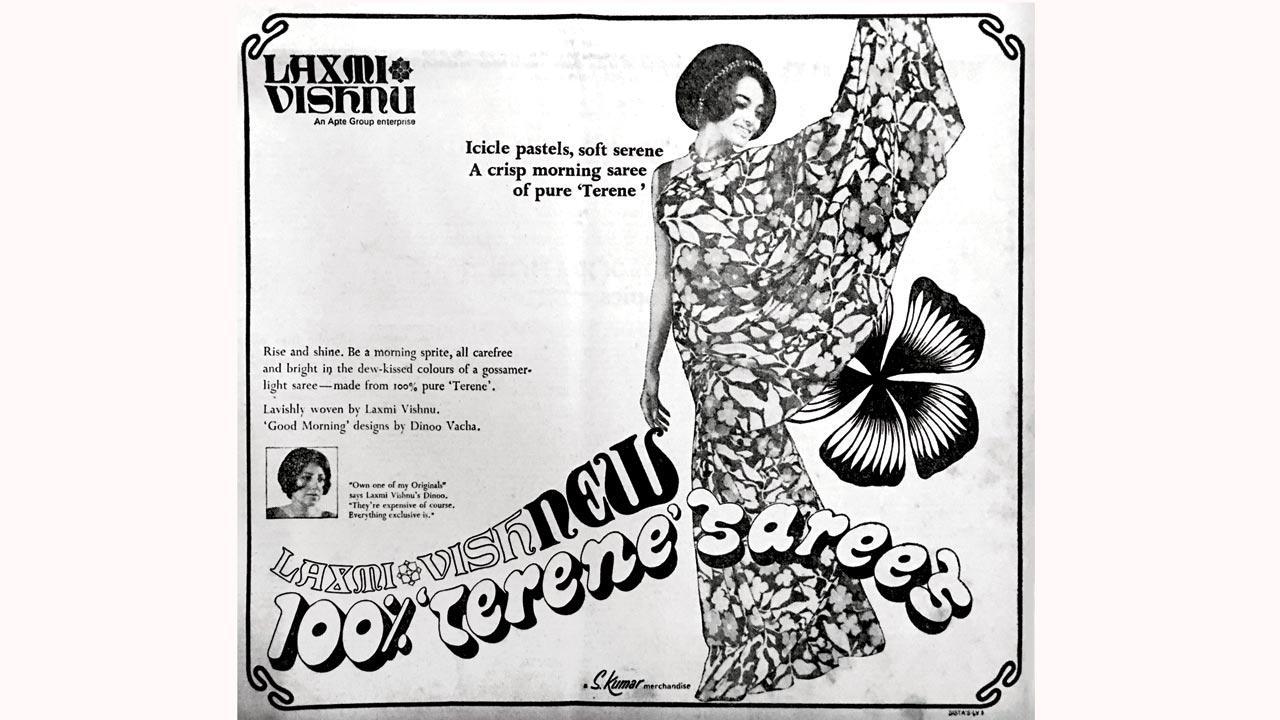

The R&D of Laxmi Vishnu Mills experimented with blending viscose fibre with polyester fibre at the spinning stage. High tech machines would then print the material as required, which would undergo a carbonisation process in which the acid would eat through the viscose, leaving behind polyester fabric. Thus the Terene saree was born. Pic Courtesy: Dhvani Terefabs Exports Pvt Ltd

To Shambhu Kumar goes too the credit for the huge success of the ‘Terene’ sari. Cotton and silk were the materials saris were woven of at that time. Silk was expensive and thus for special occasions. Cotton was best suited for daily wear and the weather conditions for most part of the year, and designs and weaves differed from state to state and region to region, offering a huge variety to choose from. Yet, cotton crumpled with wear, and with more women entering the workplace, ironing the wrinkles out became a necessary chore.

Besides, cotton took a long while to dry in the monsoon. A sari made of synthetic material might eliminate these shortcomings and find favour.